Lightweight cobots with higher payload fuel robot arms rivalry

The robot arms market is forecast to grow to $10.2 billion by 2026, versus $2.2 billion in 2021

By Oct 14, 2024 (Gmt+09:00)

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

Seoul appeal: Korean art captivates Indonesia’s affluent connoisseurs

K-pop stocks surge as China set to loosen cultural ban after 9 years

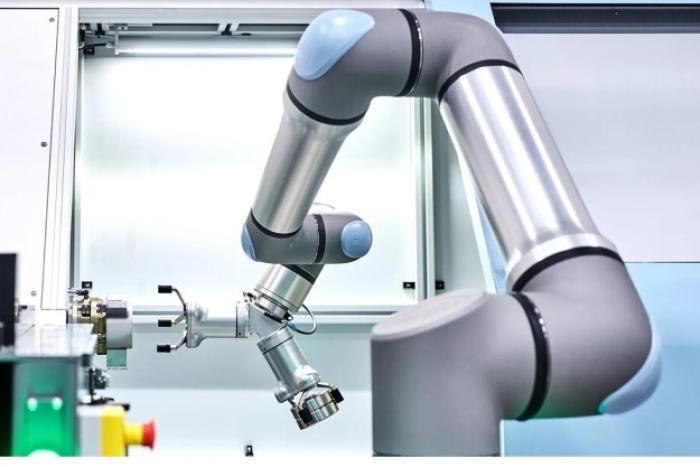

Denmark-based Universal Robots’ release of the world’s slimmest collaborative robot (cobot) with an increased lifting capacity is spurring its peers such as South Korea’s Doosan Robotics Inc. and Taiwan’s Techman Robot to develop lightweight cobots with larger payloads.

The Danish company recently unveiled an upgraded version of UR30, one of its flagship cobots, with a maximum payload of 35 kg, the largest lifting capacity for a cobot in the world.

It increased its payload by 5 kg compared with its predecessor through software enhancements. It weighs the same 63.5 kg as the previous model, the world’s lightest cobot.

The UR30 fits into automated guided vehicles, or unmanned transport vehicles that move around a logistics center to pick up and unload products.

In comparison, cobots, also called robot arms, produced by South Korea’s Doosan Robotics and Taiwan’s Techman Robot boast a lifting capacity of more than 30 kg, but weigh more than the UR30.

Universal Robots, Doosan Robotics and Techman Robot are the world’s three companies manufacturing robot arms with a lifting capacity of more than 30 kg and weighing less than 100 kg.

Boosting payload capacity without increasing weight is the key to determining the performance of cobots used in logistics automation.

Japan’s Fanuc, the world’s No. 2 industrial robot manufacturer, rolls out robot arms, the latest model of which can move products weighing up to 35 kg — the same lifting capacity as that of the UR30 — but it weighs as much as 135 kg.

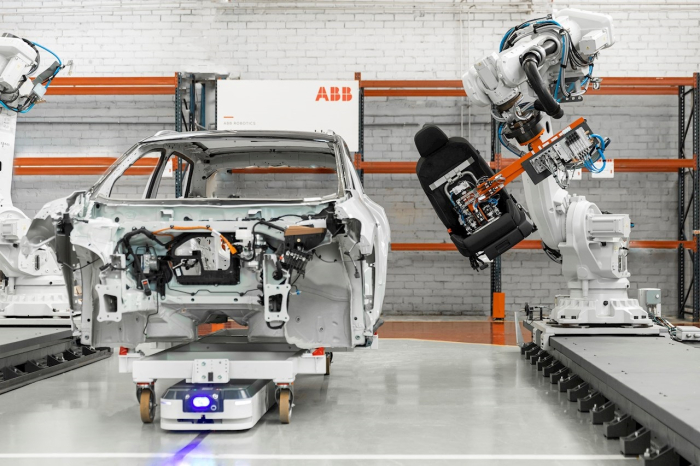

Industry observers said the release of the upgraded UR30 will boost demand for cobots used as substitutes for construction workers and other manual laborers.

“If we (people) carry a load heavier than 35 kg, we are exposed to the risk of suffering musculoskeletal disorders,” said a local robotics company official. “In the palletizing robot market, cobots will rapidly replace people.”

A palletizing robot is capable of sorting, transferring and stacking boxes or goods onto a pallet.

The robot arms market, led by palletizing robots, is forecast to more than quadruple to $10.2 billion by 2026 from $2.2 billion in 2021, according to Research and Markets.

Write to Hyeon-Woo Oh at ohw@hankyung.com

Yeonhee Kim edited this article

-

RoboticsCJ Logistics, Aidin Robotics to co-develop logistics robots

RoboticsCJ Logistics, Aidin Robotics to co-develop logistics robotsSep 26, 2024 (Gmt+09:00)

1 Min read -

Mergers & AcquisitionsDoosan Bobcat scraps merger with Doosan Robotics

Mergers & AcquisitionsDoosan Bobcat scraps merger with Doosan RoboticsAug 29, 2024 (Gmt+09:00)

1 Min read -

RoboticsDoosan Robotics supplies baggage handling robots to Dutch Airport

RoboticsDoosan Robotics supplies baggage handling robots to Dutch AirportDec 15, 2023 (Gmt+09:00)

1 Min read -

-

RoboticsDoosan Robotics eyes top spot in cobot market after Oct IPO

RoboticsDoosan Robotics eyes top spot in cobot market after Oct IPODec 08, 2023 (Gmt+09:00)

2 Min read -

RoboticsDoosan Robotics launches collaborative robot SW platform

RoboticsDoosan Robotics launches collaborative robot SW platformOct 10, 2023 (Gmt+09:00)

1 Min read -

Artificial intelligenceDoosan Robotics to develop GPT-based collaborative robots

Artificial intelligenceDoosan Robotics to develop GPT-based collaborative robotsAug 24, 2023 (Gmt+09:00)

2 Min read -

RoboticsDoosan Robotics to expand smart factory deployment using cobot

RoboticsDoosan Robotics to expand smart factory deployment using cobotJul 11, 2023 (Gmt+09:00)

1 Min read -

RoboticsDoosan Robotics launches collaborative robot dedicated to F&B

RoboticsDoosan Robotics launches collaborative robot dedicated to F&BApr 17, 2023 (Gmt+09:00)

1 Min read -