LG Chem develops material blocking battery thermal runaway

The S.Korean chemical giant plans to carry out the new material’s safety verification tests in large EV batteries through 2025

By Oct 01, 2024 (Gmt+09:00)

Samsung steps up AR race with advanced microdisplay for smart glasses

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

US auto parts tariffs take effect; Korea avoids heavy hit

LG Chem Ltd. has developed a material that can prevent thermal runaway in a lithium-ion battery, one of the major hurdles to the expansion of the electric vehicle market.

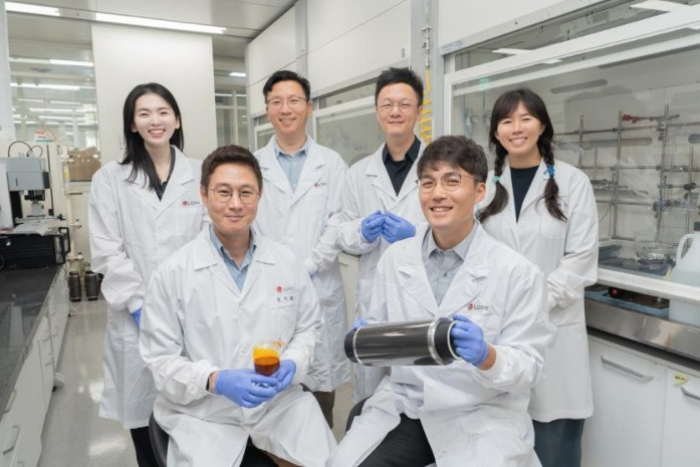

The company announced on Tuesday that its research team joined hands with the research lab led by Professor Lee Minah at the Battery Engineering Department of Pohang University of Science and Technology (POSTECH) to develop a safety-reinforced layer designed to suppress thermal runaway in lithium-ion batteries.

The achievement was published under the title of “Thermal Runaway Prevention through Scalable Fabrication of Safety Reinforced Layer in Practical Li-ion Batteries” in the September issue of Nature Communications, a peer-reviewed, open-access, scientific journal published by Nature Portfolio.

LG Chem’s battery unit LG Energy Solution Ltd. is also joining the project to evaluate the material’s safety.

“This is a tangible research achievement that can be applied to mass production in a short period,” said Lee Jong-gu, chief technology officer of LG Chem.

“We will enhance safety technology to ensure customers can use electric vehicles with confidence and contribute to strengthening our competitiveness in the battery market.”

The company plans to complete the material’s safety verification test in batteries for mobile devices this year and test its safety in EV batteries throughout next year.

EASING CONCERNS ABOUT EV FIRE RISK

The development is expected to allay concerns about the fire risk in lithium-ion batteries, often triggered by thermal runaway.

Battery thermal runaway refers to the phenomenon of electrochemical chain reactions within a battery that causes excessive heat generation in a short period, leading to battery fire or explosion.

It is caused by inner or outer mechanical, electrical or thermal shock that leads to the damage of the separator between the anode and the cathode in a battery.

The safety of EV batteries is a hot button across the globe following a series of EV battery fires.

Coupled with the prolonged EV chasm, growing fears of EV battery fires are leading more people to shun EVs.

HIGHLY EFFECTIVE IN PREVENTING THERMAL RUNAWAY

LG Chem’s battery thermal runaway suppression material is a composite material in the form of a thin layer, just 1 micrometer thick that is about 1/100th the thickness of a human hair.

It can be placed between the cathode layer and the current collector in the battery, playing the role of an electrical fuse, the Korean chemical giant explained.

When the battery’s temperature rises beyond the normal range, between 90 and 130 degrees Celsius, the newly developed material immediately reacts to the heat, with its maximum electrical resistance shooting up by over 1,000 times compared to that at normal temperatures.

But it is also highly reversible, meaning that the resistance returns to its original state once the temperature drops, allowing the current to return to normal flow.

LG Chem said both battery impact and penetration tests showed that the batteries equipped with the new material layer did not catch fire at all or that the flames were quickly contained, preventing a full-blown thermal runaway.

When it made a puncture on the surface of mobile lithium-cobalt-oxide (LCO) batteries during tests, none of the batteries reinforced with the new material caught fire, whereas more than 80% of the batteries without it did.

When the company dropped a 10-kilogram weight on nickel-cobalt-manganese (NCM) EV batteries, all of the standard batteries caught fire, whereas 70% of the batteries with the near material didn't, according to LG Chem.

The remaining 30% experienced flames but they were put down in a few seconds, the company said.

Write to Woo-Sub Kim at ter@hankyung.com

Sookyung Seo edited this article.

-

Electric vehiclesAfter Mercedes Fire, EV Owners Want to Know What Battery They Have

Electric vehiclesAfter Mercedes Fire, EV Owners Want to Know What Battery They HaveAug 21, 2024 (Gmt+09:00)

2 Min read -

Electric vehiclesHyundai, Kia to apply BMS to all EVs for fire prevention

Electric vehiclesHyundai, Kia to apply BMS to all EVs for fire preventionAug 16, 2024 (Gmt+09:00)

3 Min read -

Electric vehiclesFire-plagued Mercedes uses Chinese cells for most EVs in S.Korea

Electric vehiclesFire-plagued Mercedes uses Chinese cells for most EVs in S.KoreaAug 14, 2024 (Gmt+09:00)

2 Min read -

Chemical IndustryLG Chem develops eco-friendly flame-retardant material

Chemical IndustryLG Chem develops eco-friendly flame-retardant materialAug 12, 2024 (Gmt+09:00)

1 Min read -

Electric vehiclesHalf of EV imports in Korea run on Chinese batteries as EV fires rise

Electric vehiclesHalf of EV imports in Korea run on Chinese batteries as EV fires riseAug 09, 2024 (Gmt+09:00)

4 Min read