Lotte Energy Materials sets sights beyond copper foil: CEO Kim

Kim Yeon-seop presented an ambitious 2024 copper foil sales target of $3.6 billion, buoyed by LFP battery demand

By Jun 21, 2024 (Gmt+09:00)

Samsung steps up AR race with advanced microdisplay for smart glasses

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

US auto parts tariffs take effect; Korea avoids heavy hit

MUNICH – Lotte Energy Materials Corp. is one of South Korea’s leading battery materials specialists.

Formerly known as Iljin Materials Co., Lotte Energy has been in the industry for decades, supplying its products to global electric vehicle battery makers, including China’s BYD, Korea’s LG Energy Solution Ltd. and Samsung SDI Co.

Chief Executive Kim Yeon-seop says the time has come for Lotte Energy to take another giant leap forward.

“In a few years, Lotte will no longer be a company that only produces copper foil. We will also make base materials for all-solid-state batteries, silicon anodes and other next-generation batteries. We aim to be a top-tier battery materials maker,” he said in an interview on the sidelines of InterBattery Europe 2024 in Munich, Germany.

‘We have already received several requests from solid-state battery makers for our samples,” he said.

Battery makers and automakers are striving to develop all-solid-state batteries (ASSBs) as they feature longer mileage and a shorter charging time than existing EV batteries due to their higher energy density.

LG Energy, the world’s second-largest battery maker, said in 2021 that it had developed a next-generation solid-state battery technology that creates safer and more durable batteries than those in use.

Lotte Chemical Corp., a unit of Lotte Group, bought a controlling stake in Iljin Materials for 2.7 trillion won ($1.9 billion) in 2022 and renamed it Lotte Energy Materials.

2024 COPPER FOIL SALES SET AT $3.6 BILLION

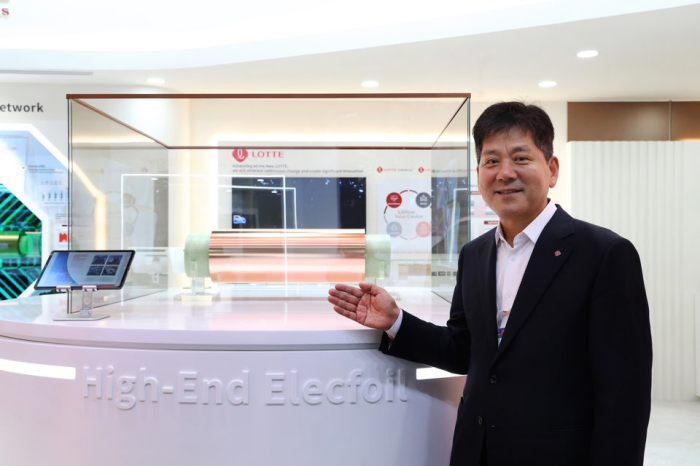

At the European battery expo, CEO Kim presented an ambitious 2024 goal to clinch 5 trillion won worth of new orders for high-end copper foil, a key battery material.

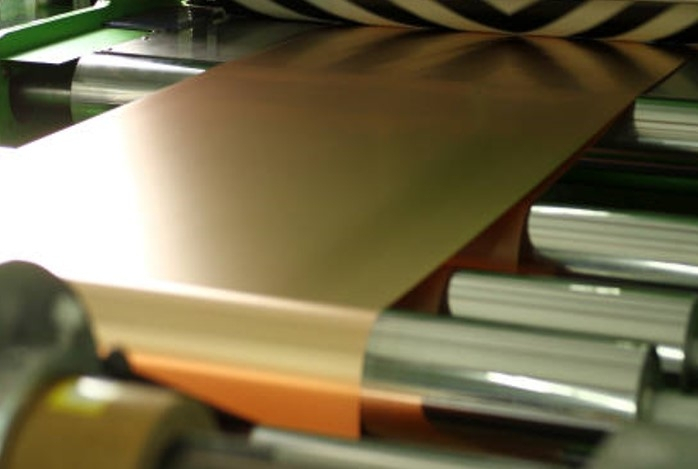

“Recent battery trends include the development of the 46 series, use of the dry manufacturing process and (demand for) improved energy density, which are impossible to achieve with existing copper foil,” he said. “Clients are increasingly demanding thinner copper foil, which requires advanced technology as it must withstand the high-speed battery manufacturing process, which generates heat.”

A copper foil, also known as elecfoil, is a thin foil that surrounds the anode, the negative end of a lithium-ion battery. High-strength copper foils are essential to making safer, high-density rechargeable batteries.

A thin copper foil less than 10 micrometers thick, made through electrolysis of a copper sulfate solution, elecfoil is also used to make cathode collectors in rechargeable lithium batteries. It is widely used in EVs and energy storage systems.

In 2022, Lotte said it developed a new ultra-high tensile elecfoil, which can significantly improve the mileage, power and stability of EVs.

The Lotte chief said in July last year that the company aims to grab 30% of the global copper foil market within the next five years by posting annual sales growth of 20% until then.

RISING LFP DEMAND TO BOOST COPPER FOIL SALES

Kim said the outlook for Lotte’s mainstay copper foil business is bright, amid rising demand for lithium iron phosphate (LFP) batteries.

LFP batteries have mainly been produced by Chinese companies such as Contemporary Amperex Technology Co. (CATL), the world’s top battery maker, and BYD while Korean battery makers have been concentrating on more expensive nickel-cobalt-manganese (NCM) cells.

However, demand for LFP cells is growing amid rising battery raw material prices and electric car makers’ penchant for low-end models. LFP batteries are also more stable, making them less vulnerable to fire, although they are lower in energy density.

The CEO said automakers are increasingly adopting high-end foil to boost the performance of LFP batteries, which are cheaper than their NCM counterparts.

Lotte Energy Materials saw its first-quarter high-end copper foil sales rise 60% from the year-earlier period.

Company officials expect high-end foils, which are ultra-thin, stronger and more elongated, to account for more than two-thirds of its new orders.

“We’re converting our production facility for general-purpose foil in Iksan, Korea to a high-end product line,” said the CEO.

Last September, Lotte said it filed for US government approval to build a copper foil plant in Delaware to meet growing demand in North America.

The company is also seeking to build a plant in Spain, set to serve as the hub for its European operations.

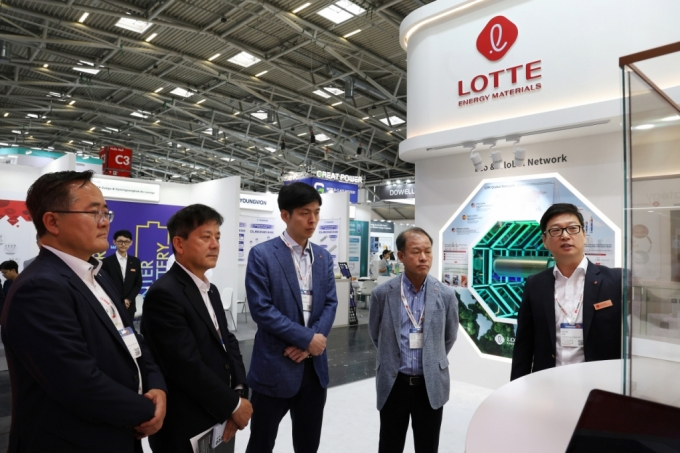

Reflecting Lotte’s keen interest in the battery material business, other senior Lotte Group executives also attended InterBattery Europe 2024. They include Shin Yu-yeol, group Chairman Shin Dong-bin’s eldest son and executive director of Lotte Holdings’ future growth business division; Lotte Chemical CEO Lee Hoon-ki; and Choi Yon-su, CEO of Lotte Infracell Co. and Lotte Aluminum Co.

Write to Sang-Hoon Sung at uphoon@hankyung.com

In-Soo Nam edited this article.

-

BatteriesPOSCO International, Lotte Energy in $4.4 bn battery materials supply deal

BatteriesPOSCO International, Lotte Energy in $4.4 bn battery materials supply dealNov 01, 2023 (Gmt+09:00)

3 Min read -

BatteriesLotte Energy Materials aspires to become copper foil leader: CEO

BatteriesLotte Energy Materials aspires to become copper foil leader: CEOJul 04, 2023 (Gmt+09:00)

3 Min read -

BatteriesLotte Energy Materials to build copper foil plant in US for EV makers

BatteriesLotte Energy Materials to build copper foil plant in US for EV makersSep 17, 2023 (Gmt+09:00)

3 Min read -

BatteriesLotte Energy ups elecfoil factory capacity in Spain to 30,000 tons

BatteriesLotte Energy ups elecfoil factory capacity in Spain to 30,000 tonsAug 07, 2023 (Gmt+09:00)

3 Min read -

BatteriesIljin Materials unveils elecfoil with ultra-high tensile strength

BatteriesIljin Materials unveils elecfoil with ultra-high tensile strengthSep 16, 2022 (Gmt+09:00)

1 Min read