Steel

S.Korean steelmakers mull building electric furnaces in US

Washington may sharply raise tariffs on Chinese steel products if Donald Trump is elected as president in November

By Mar 11, 2024 (Gmt+09:00)

2

Min read

Most Read

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

US auto parts tariffs take effect; Korea avoids heavy hit

NCSOFT invests in US game startup emptyvessel

Steelmakers are considering building steel mills with electric furnaces in the United States to survive the triple whammy of high tariff barriers, low emission requirements and stiff price competition from Chinese competitors.

Hyundai Steel Co., South Korea’s No. 2 steel producer after POSCO Holdings Inc., recently converted its green steel task force, a temporary in-house operation established to prepare for the decarbonization era, into a permanent division, according to industry officials on Sunday.

The division is studying whether to build a steel mill operating electric furnaces in the US, the world’s largest steel market. At present, no Korean steelmakers operate a blast or electric furnace plant there.

A Hyundai Steel official told The Korea Economic Daily that no decision has been made on whether or not to construct a steel mill with electric furnaces in the US.

US TARIFFS

Since then, Korea and Japan have been allowed to export tariff-free up to 70% of their average export volume of the previous three years. They must pay a 25% tariff for additional shipments.

However, the US tariff policy could work in their favor, if Trump, the likely Republican candidate, wins the November election.

During his presidential campaign, Trump pledged to sharply raise tariffs on Chinese steel to more than 60%.

If that occurs, Korean and Japanese steel makers are expected to avoid a price war with China, which is dumping steel products on overseas markets to make up for waning domestic demand.

CARBON TAXES

In addition to import tariffs, Washington has decided to levy a tax of $55 per ton of greenhouse gas emissions on 12 imported products, including steel, starting this year. It is now fine-tuning details of the tax policy.

An electric furnace melts scrap metal with electricity, and so it emits 80% less carbon than blast furnaces that use iron ore and bituminous coal, a main culprit in greenhouse gas emissions.

Electric furnaces are also cost-effective. It costs 500 billion to 1 trillion won ($380 million-$760 million) to build an electric furnace — much less than the 3 trillion won needed to construct a blast furnace.

Quality could be a concern, however.

Because steel produced in electric furnaces is made from iron scrap, it contains more impurities than steel from iron ore made in blast furnaces. Thus, it cannot meet the qualifications for high-end materials such as automotive steel sheets.

POSCO and Hyundai Steel hope to address the problem by mixing molten iron from a blast furnace with melted steel scrap to be used in electric furnaces.

Meanwhile, instead of making a greenfield investment in the US, Japan's Nippon Steel Corp., the world's fourth-largest steel maker, chose a shortcut to access the US market.

In December, it agreed to acquire US Steel, the world's third-largest steel company, for $14.1 billion.

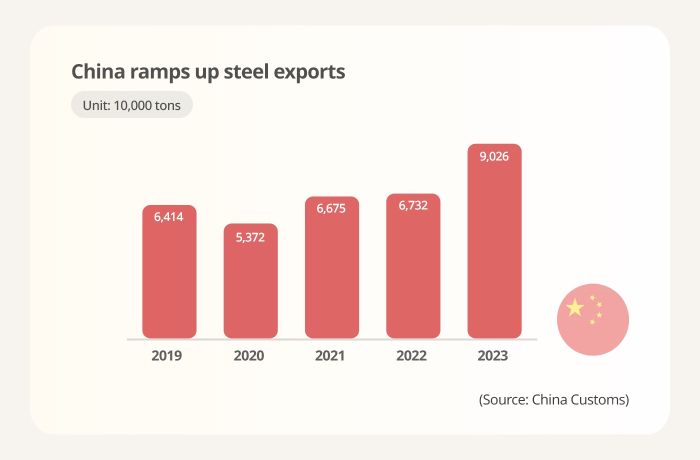

According to China Customs, China's exports of finished steel products amounted to 90.26 million tons in 2023, up 36.2% from the previous year.

Some 9.6% of the total came to Korea, where it sold more more than 10% less than equivalent Korean products.

Write to Woo-Sub Kim at duter@hankyung.com

Yeonhee Kim edited this article

More to Read

-

-

-

SteelKorean steelmakers mull anti-dumping suit vs Chinese, Japanese firms

SteelKorean steelmakers mull anti-dumping suit vs Chinese, Japanese firmsJan 17, 2024 (Gmt+09:00)

3 Min read -

-

-

Comment 0

LOG IN