Korean SMEs

Chemtronics readies to produce key solvent for photoresists

Photoresists have been slow to manufacture in Korea due to the difficulty in producing high-purity solvents

By Nov 07, 2023 (Gmt+09:00)

2

Min read

Most Read

Samsung steps up AR race with advanced microdisplay for smart glasses

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

US auto parts tariffs take effect; Korea avoids heavy hit

SEONGNAM, South Korea -- Chemtronics Co. Ltd., a South Korean chemical materials maker, appears to have removed a key hurdle to expanding the domestic production of photoresists.

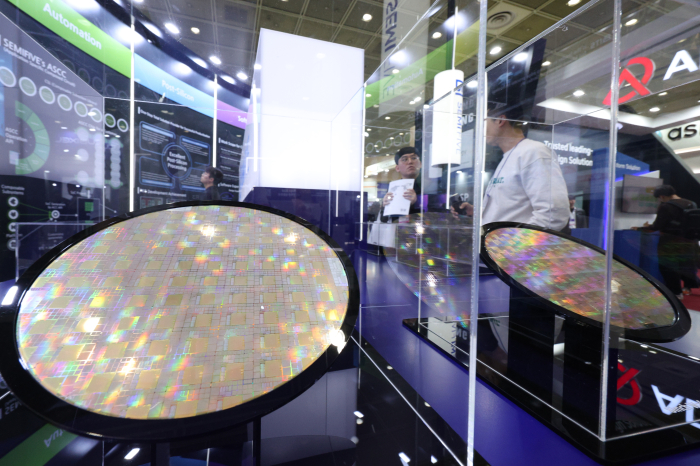

Photoresists are among the three core materials for semiconductors and displays, for which Japan has imposed controls on exports to South Korea since 2019.

Kosdaq-listed Chemtronics recently succeeded in test-producing propylene glycol methyl ether acetic acid (PGMEA) with high purity. It accounts for a large portion of the manufacturing process of photoresists.

Due to the difficulty in producing solvents with ultra-high purity, domestic production of photoresists has been slow compared with the two other materials -- hydrogen fluoride and fluorinated polyimide -- under export controls by Japan.

Photoresists are used to produce extreme ultraviolet (EUV) lithography that draws patterns on the substrates of semiconductor chips and display panels.

Up until now, Chemtronics has purchased PGMEA from Japan and Taiwan and refined it to improve purity.

Utilizing its own synthesis and refining know-how, the company is about to mass-produce the solvent with a purity of 99.999% (5N), four years after launching its development.

The solvent is now undergoing quality testing by its major customer. It Is scheduled for mass production from the first half of 2024, Kim Eung-soo, chief executive of Chemtronics, said on Tuesday.

It built the mass production lines of the PGMEA with a capacity of 10,000 tons by investing 24 billion won ($18 million) last year. Additionally, it plans to invest 17.2 billion won this year to more than double its production capacity to 25,000 tons, according to its regulatory filing on Tuesday.

As a thinner, PGMEA washes away photosensitive materials from the areas where photosensitive reaction does not occur during the EUV process.

CEO Kim said the use of a photoresist made of solvents with a 5N-level purity will significantly reduce defects caused by metallic residue.

Further, its PGMEA has sharply lowered the ratio of a potentially toxic substance, called beta-isomer, in line with the global companies’ request to cut the beta-isomer concentration ratio to below 10 ppm (parts per million).

The PGMEA produced by Chemtronics has an even lower ratio of 1ppm.

Meanwhile, another Korean company Jaewon Industrial Co. started mass production of the PGMEA last year.

The PGMEA market is predicted to grow to 1 trillion won by 2024 from 926.2 billion won in 2022.

Write to Byung-Keun Kim at Bk11@hankyung.com

Yeonhee Kim edited this article.

More to Read

-

Korean chipmakersKorean chipmakers to cut core solvent imports for EUV process

Korean chipmakersKorean chipmakers to cut core solvent imports for EUV processFeb 18, 2022 (Gmt+09:00)

2 Min read -

Korean chipmakersSamsung makes industry’s smallest 14 nm DDR5 chip with EUV technology

Korean chipmakersSamsung makes industry’s smallest 14 nm DDR5 chip with EUV technologyOct 12, 2021 (Gmt+09:00)

4 Min read -

Chemical IndustrySumitomo Chemical to build $90 million photoresist plant in S.Korea

Chemical IndustrySumitomo Chemical to build $90 million photoresist plant in S.KoreaSep 01, 2021 (Gmt+09:00)

2 Min read

Comment 0

LOG IN