Hyundai Glovis, Huayou join hands for EV battery recycling

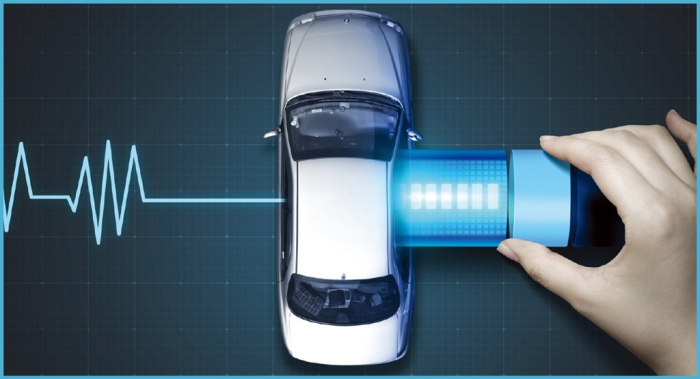

Hyundai Glovis is developing battery diagnosis systems with Hyundai Motor Group for mass production in 2025

By Aug 06, 2024 (Gmt+09:00)

When in S. Korea, it’s a ritual: Foreigners make stops at CU, GS25, 7-Eleven

Maybe Happy Ending: A robot love story that rewrote Broadway playbook

NPS yet to schedule external manager selection; PE firms’ fundraising woes deepen

Samsung steps up AR race with advanced microdisplay for smart glasses

Seoul appeal: Korean art captivates Indonesia’s affluent connoisseurs

Hyundai Glovis Co., the logistics unit of South Korea’s Hyundai Motor Group, has teamed up with a unit of China’s Zhejiang Huayou Cobalt Co., the global refined cobalt leader, for the fast-growing electric vehicle battery recycling business.

Hyundai Glovis on Monday agreed with Huayou Recycling Technology Co., a wholly owned subsidiary of Huayou Cobalt, to cooperate on the establishment of retired EV battery circulation systems, the energy storage system (ESS) business and raw materials supply management.

“EV batteries can be used for ESS when their remaining capacities fall to 80-90%, while raw materials such as cobalt, nickel and lithium can be extracted through decomposition and melting them,” said a battery industry source in Seoul.

The global retired battery recycling industry was forecast to grow to $208.9 billion by 2040 from an estimated $42.4 billion in 2030, Hyundai Glovis quoted South Korean EV and battery industry tracker SNE Research as saying.

FUTURE GROWTH

Huayou Recycling known for its technology to check batteries’ remaining capacity in 15 seconds collects 65,000 tons of retired batteries enough for over 130,000 EVs a year in China, the world’s largest clean vehicle market.

“There is no choice but to seek out Chinese companies, given few waste battery suppliers in Korea,” said a shipping industry source in Seoul. “Various technologies are required to safely transport large-capacity batteries by sea for long periods.”

Hyundai Glovis, the major shareholders of which include Hyundai Motor Co., the maker of the IONIQ EV series, has been working on the battery recycling business for future growth.

The logistics company developed a dedicated container to carry multiple retired batteries, for which it obtained a patent in 2021. It made an equity investment in ER, a South Korean company with the technology of pre-treatment processes of waste batteries, earlier this year.

Hyundai Glovis is also developing battery diagnosis systems with Hyundai Motor Group’s Namyang R&D Center, the conglomerate research hub, for mass production in 2025.

The company also joined hands with EcoPro Co., South Korea’s leading EV battery materials producer, for the battery recycling business in June.

Write to Jin-Won Kim at jin1@hankyung.com

Jongwoo Cheon edited this article.

-

BatteriesHyundai Glovis, EcoPro team up for EV battery recycling business

BatteriesHyundai Glovis, EcoPro team up for EV battery recycling businessJun 03, 2024 (Gmt+09:00)

1 Min read -

BatteriesHyundai Glovis to build waste battery management in Jeju

BatteriesHyundai Glovis to build waste battery management in JejuMay 16, 2024 (Gmt+09:00)

1 Min read -

BatteriesLG Energy, Huayou Cobalt set up battery recycling JV in China

BatteriesLG Energy, Huayou Cobalt set up battery recycling JV in ChinaAug 08, 2023 (Gmt+09:00)

2 Min read -

BatteriesLG Energy, China’s Huayou Cobalt to build battery recycling joint venture

BatteriesLG Energy, China’s Huayou Cobalt to build battery recycling joint ventureJul 26, 2022 (Gmt+09:00)

4 Min read