Ultium Cells Spring Hill: LG, GMŌĆÖs EV battery bastion in North America

LG EnergyŌĆÖs battery plant in Tennessee will serve as its US base for business expansion

By Jun 04, 2024 (Gmt+09:00)

S.Korea's LS Materials set to boost earnings ahead of IPO process

Affirma Capital seeks to sell entire stake in both SeAH FS, S&G Holdings

SK asks KDB for further funding before drastic restructuring

EcoPro BM in talks to produce sodium-ion battery cathodes

Hyundai to transform Jeonju plant into hydrogen vehicle hub

NASHVILLE ŌĆō Some 60 km south of Nashville, the capital of Tennessee, lies a huge plant churning out battery cells that will eventually land in sleek, premium electric vehicles such as the Cadillac Lyriq and the Chevrolet Equinox.

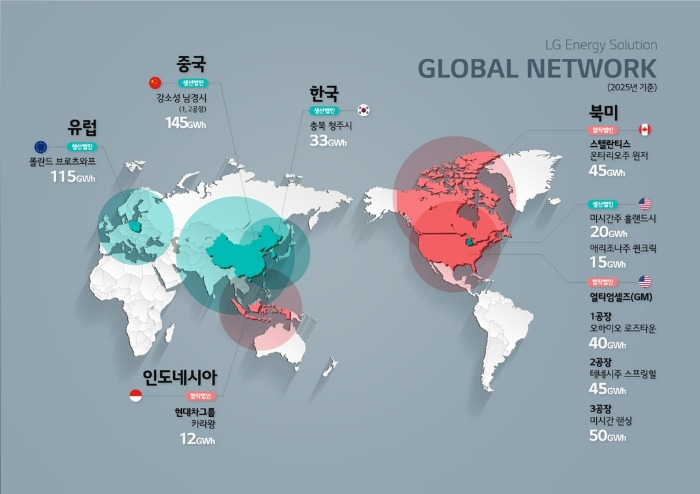

Located on a 247,000-square-meter plot of land, about 35 times the size of a soccer field, Ultium Cells Spring Hill is the $2 billion joint venture between South KoreaŌĆÖs LG Energy Solution Ltd., the worldŌĆÖs second-largest battery maker, and General Motors Co.

The LG-GM joint venture, Ultium Cells LLC, put the Spring Hill factory with a production capacity of 35 gigawatt hours (GWh) into operation in March.

The plant, Ultium CellŌĆÖs second battery cell manufacturing facility in the US, is slated to gradually ramp up its output capacity to 50 GWh, enough to power 600,000 high-performance pure electric cars that can run 500 km on a single charge.

LG says the new plant is running on a cutting-edge smart factory system to maximize productivity through an automated manufacturing process and quality inspections.

SIMULATORS

Among the most notable facets of the smart system, according to Ultium Cells officials, are the 16 simulators inside the plant, which virtually teach new employees what itŌĆÖs like to work on every production line.

ŌĆ£Battery work could be complicated for new workers. The simulators play a big role in getting them accustomed to job sequences and increase productivity as a result,ŌĆØ Kim Young-duck, chief of the second plant, said last Thursday when he opened the factory to journalists for the first time since its launch.

Kim, who oversaw the development of the simulators, said: ŌĆ£The second factory, built on LGŌĆÖs solid partnership with GM, will grow into a core base for the North American electric vehicle market along with the first and third factories.ŌĆØ

First batches of pouch-type batteries ŌĆ£made by Ultium Cells Spring HillŌĆØ have already been delivered to GM for the US automakerŌĆÖs latest EV models, including the Cadillac Lyriq and the Chevrolet Equinox.

Compared to LGŌĆÖs other battery plants in the US and globally, the Spring Hill plant boasts of a high product yield, or the percentage of products that meet quality standards.

ŌĆ£In just one month into operation, the plant achieved a product yield of over 90%, which is remarkable,ŌĆØ he said.

For LG EnergyŌĆÖs battery plant in Poland, which was completed in 2018, it took more than a year to reach the 90% yield.

CATHODE PLANT IN CLARKSVILLE

In Clarksville, 140 km north of the Spring Hill battery plant, LG Chem Ltd., parent of LG Energy and KoreaŌĆÖs largest chemical company, is building a cathode plant, a key EV battery material.

The plant broke ground last December and the foundation work is under way.

Once up and running, the plant will produce 60,000 tons of cathode materials annually, enough to make batteries for 600,000 pure EVs.

LG Chem has already signed a 25 trillion won ($18 billion) contract to supply cathode materials to GM.

Last October, the company also signed a 2.9 trillion won deal to supply cathode materials to Toyota Motor's US battery plant, Toyota Motor Engineering & Manufacturing North America.

LG Chem said the Clarksville cathode plant, when completed in 2026, will serve as its North American customer base.

TRIANGULAR PRODUCTION BELT

The production complex LG Group is building in Tennessee is emerging as LGŌĆÖs main production base in North America.

The ŌĆ£triangular production beltŌĆØ that houses LG plants for home appliances, batteries and battery materials, boasts high production yields and large-scale production capacity.

LG said the Tennessee production belt is its bridgehead to the US market, where the business environment is rapidly changing due to the US-China conflict.

To the east of LG's Tennessee battery facilities lies the LG Highway, which connects Spring Hill to Clarksville, also home to LG Electronics Inc.ŌĆÖs washing machine plant. The Tennessee state government named it LG Highway in 2018 to commemorate the completion of the LG washing machine plant.

LG says its plants in Tennessee are strategically located as the state borders eight other states, including Georgia and Alabama, home to large international companies.

ŌĆ£Tennessee's population is growing, particularly young people, even after the pandemic, making it easier to secure employees,ŌĆØ said an LG official.

Write to In-Seol Jeong at surisuri@hankyung.com

In-Soo Nam edited this article.

-

RegulationsLG Energy vows to get tough on battery patent infringement cases

RegulationsLG Energy vows to get tough on battery patent infringement casesApr 24, 2024 (Gmt+09:00)

4 Min read -

BatteriesLG Energy, GMŌĆÖs 2nd Ultium Cells plant begins production in Tennessee

BatteriesLG Energy, GMŌĆÖs 2nd Ultium Cells plant begins production in TennesseeApr 02, 2024 (Gmt+09:00)

2 Min read -

BatteriesLG Energy to produce 4680 batteries in August for Tesla, others: CEO

BatteriesLG Energy to produce 4680 batteries in August for Tesla, others: CEOFeb 15, 2024 (Gmt+09:00)

4 Min read -

BatteriesLG Energy to supply $748 million worth of batteries to JapanŌĆÖs Isuzu Motors

BatteriesLG Energy to supply $748 million worth of batteries to JapanŌĆÖs Isuzu MotorsJan 26, 2024 (Gmt+09:00)

1 Min read -

BatteriesLG Energy, KAIST develop Li-Metal battery tech for improved EV range

BatteriesLG Energy, KAIST develop Li-Metal battery tech for improved EV rangeDec 07, 2023 (Gmt+09:00)

3 Min read -

BatteriesLG Chem to supply cathode materials to Toyota's N.American plant

BatteriesLG Chem to supply cathode materials to Toyota's N.American plantOct 11, 2023 (Gmt+09:00)

1 Min read